How to Start Stone Crusher Plant Project Business in 5 Steps

Do you want to start a stone crusher plant business? If so, find here a complete project plan guide on launching a stone crushing plant with costs, licenses, production process, and much more.

Stone chips are one of the main construction materials along with bricks, sand, cement, and steel. Generally, you can segregate the crushed stone into various sizes like 35mm, 20mm, 12mm, etc for different uses. Crushed stone aggregates are essential for the construction of roads, bridges, housing, industrial buildings construction.

Additionally, it is an essential item for other cement-based products. The list includes RCC pipes, PSC poles, pre-molded slabs, frames, and beams, etc for fabrication. A stone crusher plant is a profitable venture for new entrepreneurs. The demand for quality stone chips is increasing day by day.

Market Growth of Stone Crushing Industry

The growing adoption of stone crushers in various sectors such as mining, infrastructure & building, highways and railways, will drive the stone crushing equipment market growth over the forecast timeline. The surge in mining activities in Asian economies has resulted in the increased utilization of this machinery in the region. Continuous development of roads and highways due to the increasing transportation activities across the globe, will contribute to the market demand.

Here are the 5 Steps to Follow to Start Stone Crusher Plant Business

Want more information, contact us by jycrusher@hotmail.com

1. Land and Portable stone crusher machine

They are the major fixed cost investment. Major working capital costs are raw material, manpower, and utilities. Under the PMEGP scheme, you can get the subsidy from the banks. In the project funding, there must be a percentage of promoter’s allocation of the fund. Bank can ask for collateral security deposit also on the loan amount.

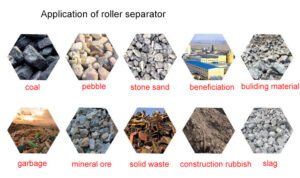

2. Granite crusher & Raw Materials

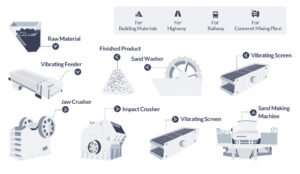

Stone crusher plant machinery depends on the feed size of the stone, the desired product size and the size of the crusher used. Following are the generally required machinery, jaw crusher and granulator, conversion kit for converting crushed stone granules, set of hoppers for manual breaking, rotary screen completes with all fittings, trollies for carrying crushed material, spare jaws, jigs, fixtures and tools.

Stone crusher plants are available in two major type namely (a) stationary (b) portable or mobile. However, you can establish stationary crushers at quarry heads. Mainly, at the construction site, you can use the portable crushers.

Diamond, quartz, lime stone, sandstone, granite stone, are all the raw materials for stone crusher machine.

3. Production Process

First of all, break the big stone boulders into smaller sizes manually. Then it is fed to the stone crusher. The crusher can accept stone size of 175mm. Stone crushing is a two-stage process. In the first

stage, crush the 175mm stone to about 50mm.

Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm. Then screen the crushed material by the rotary screen. Unit location is a major factor for the stone crusher plant business.

4. Reliable Stone crusher machine machinery Supplier

A reliable machine supplier is generally an OEM factory, who provide you technics and guidience during producing.

5. Selling products to Concrete station or retailers.

You will get profit after selling the products to Concrete station or retailers.