6 Tips Help To Make High Quality Artificial Sand from Sand Washing Plant

6 Tips Help To Make High Quality Artificial Sand from Sand Washing Plant

With the increasing number of construction projects, the amount of concrete is increasing. And the demand for sand is also increasing. High quality artificial sand can meet the sand demand of different construction projects. So how to make high quality artificial sand? You need to consider 6 tips: raw materials, sand making equipments, production process, quality control, etc.

Ⅰ. Selection of Raw Materials

The parent rock used for processing artificial sand, shall not have potential alkaline aggregate reactivity, and the compressive strength shall not be less than 80MPa. It should be produced with clean, hard rock without soft particles and wind fossils. Before selecting raw materials, the rock base material shall be sampled for test, and the rock compressive strength, lithology, sulfide and sulfate content shall meet the requirements to ensure the quality of raw materials.

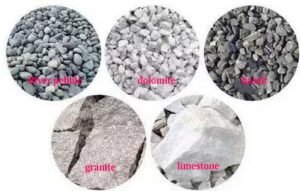

There are many rocks that can be used as raw materials of artificial sand, including granite, basalt, river pebble, cobble, limestone, calcite, andesite, rhyolite, diorite, diabase, sandstone, tailings, slag, quartzite, etc. the artificial sand made of different rocks varies in strength, particle size and application scenarios.

Uses of artificial sand with different raw materials:

1) Sandstone: the content of quartz is high, so it is widely used in sand and gravel production line, the problem of stone powder content should be solved in production。

2) Quartz sandstone: quartz sandstone is a good raw material for sand making, which can reach or even better than natural sand in strength and grain shape.

3) River pebbles: River pebbles are also a good quality raw material for sand production, and they are a good choice to replace natural sand in terms of strength, grain shape and chromaticity.

4) Limestone: in the sand and gravel production line, it can be used as the raw material of sand and stone at the same time, and the stone powder can be reused at the same time.

5) basalt: the sand made of basalt is mixed into concrete, which can reduce the weight of concrete, but it is still very strong, and it has the characteristics of sound insulation and heat insulation, so it is a good aggregate for lightweight concrete in high-rise buildings.

6) Granite: granite with high quartz content and low sulfide content is a good raw material for sand making, but the problem of powder should be solved.

The mud blocks in artificial sand are mainly carried by blocks and stones that produce sand. When mining mines, clean surface vegetation and soil should be removed to prevent weathered sand, soil and other sundries from mixing. In the process of feeding, the block stone should be further screened by the vibrating feeder, and the screened soil and small pieces of gravel can not be mixed into the sand.

The leftoer material after the production of crushed stone is processed into stone powder, pebbles and other by-products, which can not only effectively supply the aggregate market to achieve good economic benefits, but also solve waste water pollution and waste of resources.

Ⅱ. Sand screening and washing machine Equipments and Process

The main production processes include: Mine block stone → coarse crushing → medium crushing → fine crushing → screening → dust removal → artificial sand.

Crushing processes and equipments combination include:

- a. Jaw crusher + impact crusher;

- b. Jaw crusher + cone crusher;

- c. Jaw crusher + roller crusher;

- d. Jaw crusher + impact crusher + impact sand shaping machine (common);

- e. Jaw crusher + cone crusher + impact sand shaper or sand making system (common).

High quality artificial sand production process:

- a. According to the separation method of stone powder, it can be divided into “wet sand”, “dry sand” and “semi dry sand”;

- b. According to the process flow, it can be divided into “separate sand making” and “combined sand making”;

- c. According to the structural form, it can be divided into “plane sand making” and “floor sand making”.

At present, the separation methods of stone powder mainly include dry method, wet method and semi dry method. Dry process production adopts air separation stone powder, and realizes particle size adjustment and stone powder screening through air separation technology;

The stone powder is washed by sand washing machine in wet production. The equipment mainly includes wheel sand washing machine or spiral sand washing machine. The loss of fine sand and stone powder of wheel sand making machine is less, and the output of artificial sand is well graded, but the output is slightly small.

Ⅲ. Control of Fineness Modulus

At present, the general requirement of fineness modulus of artificial sand is medium sand. Through practice, the mesh diameter of artificial sand produced by dry method is easy to be controlled below 5mm, and that of water washing machine-made sand is easy to be controlled below 3.2mm. However, if the pore size of the washed artificial sand screen is controlled at 4mm, the output can be greatly increased, but the fineness modulus can reach coarse sand, which can reach medium sand by mixing with natural fine sand.

The grain shape of artificial sand is mainly affected by the development of lithologic joints of parent rock, the type of crushing equipment and the type of screen, the lithology of parent rock affects the crushing surface and crushing degree of rock, the forming effect of impact crusher is better, and the square hole screen controls the grain shape better.

The particle gradation of artificial sand can be realized by adjusting feed gradation, feed quantity, crusher speed, screen size and so on.

IV. Control of Stone Powder Content

Artificial sand contains a small amount of stone powder smaller than 0.075mm in the production process. Artificial sand containing a certain amount of stone powder, is of great help to improve the working performance of medium and low strength concrete, but has almost no effect on the strength of concrete. However, when the content of stone powder is high, it has an adverse effect on the preparation of high-strength concrete. Therefore, how to remove and control the excess stone powder in machine-made sand is one of the key technologies in the production of machine-made sand.

The smaller the fineness modulus of artificial sand is, the finer the particles are and the more the stone powder content is. It is not advisable to reduce the fineness modulus simply by increasing the stone powder content in production. As these two technical indicators rise and fall and conflict with each other, it is necessary to find an interval where both of them meet the requirements of the specification.

At present, the main methods used are dry dust collection and wet washing. Dry dust collection is to select the dust collector with good dust collection effect, and determine the working condition parameters of the dust collector according to the requirement of stone powder content in artificial sand, but this method is only suitable for the production of class III artificial sand. Washing and removing powder from artificial sand is the key technology to produce high quality machine-made sand, but attention should be paid to water saving and environmental protection.

Ⅴ. Control of Crushing Index

The crushing index of artificial sand is used to measure the crushing resistance of machine-made sand under increasing load, in order to evaluate its applicability in engineering, and is an important index to indirectly express the firmness of artificial sand. The crushing index directly affects the strength of the prepared concrete, especially for high strength concrete.

The crushing index of artificial sand with better particle shape is generally in the range of 20% to 25%. Artificial sand with a crushing index value of less than 30% should be used to mix ordinary concrete. The main production control measure is to select the rock with high compressive strength and good rock mass integrity to make sand.

| Crushing Index of Artificial Sand | |||

|---|---|---|---|

| Concrete strength grade | ≥C60 | C55-C30 | ≤C25 |

| Maximum crushing value(%) | <20 | <25 | <25 |

VI. Control of Segregation

Practice shows that the segregation of artificial sand is serious, which leads to great differences in gradation and fineness modulus before and after entering the market. For dry production, wet mixing treatment should be carried out, and a water spraying device can be installed on the belt conveyor, but excessive water spraying should be avoided to cause local concentration of stone powder and small particles.

The artificial sand of the finished product should be piled reasonably, and the ascending inclined stacking method should be adopted to prevent the small particle diameter from slipping and accumulating, and the inclined slope should be set reasonably according to the area of the reservoir area and the stacking height. Choose a relatively flat public transport road, try to smooth access to the concrete station construction access road, properly control the vehicle speed, and reduce the artificial sand segregation caused by vehicle bumps. In the process of unloading, lift the box as much as possible to facilitate the rapid decline of materials and reduce the accumulation of coarse particles to the outside.