Mobile Crusher

A Mobile Stone Crusher is a machine that is designed to crush large rocks into smaller rocks, gravel, or rock dust. It is primarily used in the mining, construction, and recycling industries.

Mobile stone crushers can be operated either as standalone units or as part of a larger fleet. They are designed to be highly portable and easy to transport between job sites. This allows them to be used in a variety of different locations, including remote areas where traditional crushers may not be feasible.

Some common features of mobile stone crushers include:

- A compact design that makes them easy to transport and maneuver

- A powerful engine that enables them to crush even the toughest rocks and materials

- A hydraulic system that adjusts the crusher settings to optimize performance and ensure consistent product quality

- A variety of screening options that allow for the separation of different sized materials

- A remote control system that allows the operator to easily adjust settings and monitor performance from a safe distance

Overall, mobile stone crushers offer a convenient and efficient solution for crushing rocks and other materials on the go.

What Is The Difference Between The Fixed Crusher Plant And Mobile Crusher Plant

The main difference between a fixed crusher plant and a mobile crusher plant is that a fixed crusher plant is stationary and cannot be moved from one location to another, while a mobile crusher plant can be easily transported between different job sites.

Fixed crusher plants are typically large-scale operations that are designed to process large quantities of material over an extended period of time. They are commonly used in mining and quarrying operations, where the material being processed is of a consistent quality and is produced in large quantities. Fixed crusher plants usually require a significant amount of infrastructure, such as access roads, power supplies, and water sources, which can make them expensive to set up.

On the other hand, mobile crusher plants are designed to be highly portable and easy to transport between different job sites. They are typically smaller in size than fixed crusher plants and are designed to be set up and taken down quickly. Mobile crusher plants are often used in construction and demolition projects, where the material being processed may vary in quality and quantity from one job site to another.

Mobile crusher plants also offer the flexibility to adjust the crushing process based on the type and size of material being processed. For example, a mobile crusher plant can be equipped with different types of crushers, screens, and conveyors to process different types of materials and produce different sizes of crushed stone.

Overall, the choice between a fixed crusher plant and a mobile crusher plant will depend on the specific needs of the job and the resources available to the operator. Fixed crusher plants are better suited for long-term, large-scale operations, while mobile crusher plants offer greater flexibility and portability for shorter-term or smaller-scale projects.

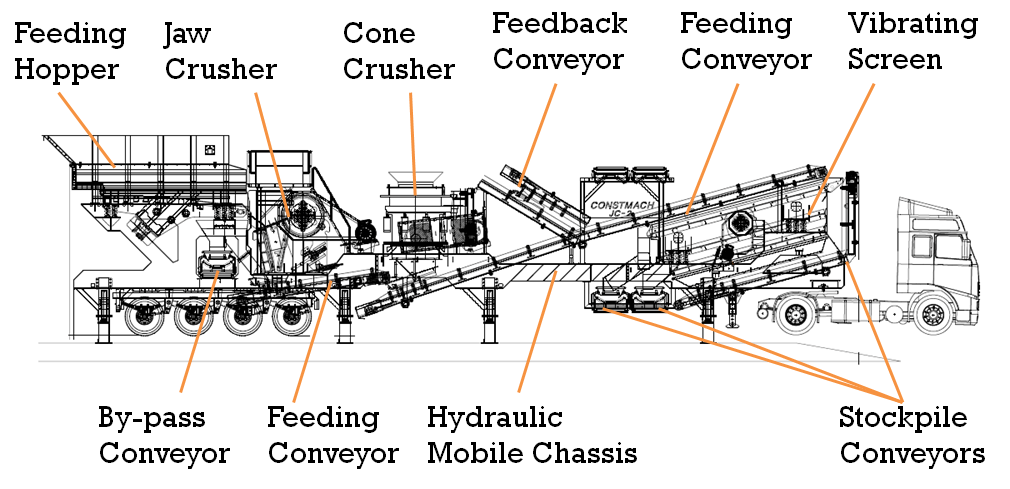

What Is The Mobile Crusher Plant Consist Of ?

A mobile crusher plant consists of several components that work together to process different types of materials and produce different sizes of crushed stone. The exact configuration of a mobile crusher plant can vary depending on the specific needs of the job, but some common components include:

- Primary Crusher: The primary crusher is the main machine used to crush the raw material into smaller pieces. This can be a jaw crusher, impact crusher, or cone crusher, depending on the type of material being processed.

- Feeder: The feeder is responsible for delivering the raw material to the primary crusher. It can be a vibrating feeder or a conveyor belt, depending on the specific needs of the job.

- Secondary Crusher: The secondary crusher is used to further break down the crushed material into smaller pieces. This can be a cone crusher or impact crusher.

- Screening Equipment: The screening equipment is used to separate the crushed material into different sizes. This can be a vibrating screen or a trommel screen.

- Conveyor System: The conveyor system is used to transport the material between different stages of the crushing process. This can include both belt conveyors and stackers.

- Control System: The control system is used to monitor and control the operation of the mobile crusher plant. This can include a central control panel or a remote control system.

- Power System: The power system provides the electricity needed to operate the mobile crusher plant. This can include a generator or connection to an external power source.

Overall, a mobile crusher plant is designed to be a flexible and portable solution for processing different types of materials and producing different sizes of crushed stone. The specific configuration of the plant will depend on the needs of the job and the resources available to the operator.