Vertical Shaft Impact (VSI) crushers

Capacity

30-600t/h

Max feeding size

45mm-150mm

Raw materials

Iron ore, copper ore, cement, artificial sand, fluorite, limestone, slag, etc.

Application

Engineering, highway,railway, passenger line, bridges,airport runways,municipal engineering,high-rise

Features and technology advantages of Vertical Shaft Impact (VSI) crushers

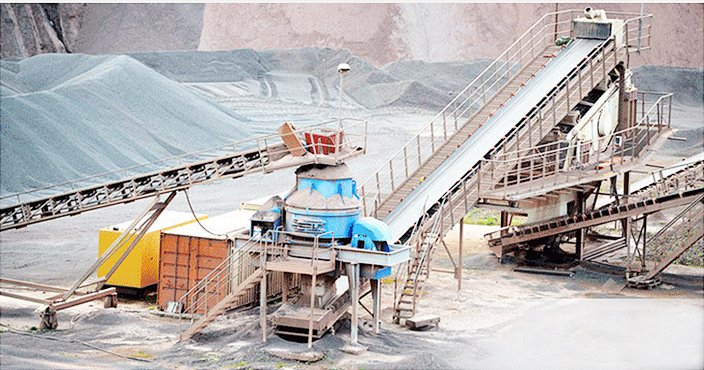

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate.

Application of Vertical Shaft Impact (VSI) crushers

VSI Impact Crushers are suitable for manufactured sand, re-crush of slow selling stocks, cubical products fractured gravel, material beneficiation, crushing of cement clinker before mills and glass recycling applications.

River stone, mountain stone(limestone, basalt, granite, diabase, andesite.etc), Ore tailings, aggregate chips.

Hydraulic and hydroelectric engineering, high-level road, highway and railway, passenger rail line, bridge, airport runway, municipal projects, sand making and rock reshaping.

Building aggregate, highway road fabrics, cushion material, asphalt concrete and cement concrete aggregate.

Crushing progress before grinding in mining field. The crushing of building material, metallurgy, chemical industry, mining, fireproofing, cement, abrasive, etc.

Breaking of high abrasive and secondary disintegration, sulfur in thermal power and metallurgy industry, environmental projects such as slag, construction waste crushing.

Manufacturing of glass, quartz sand and other high purity material.

Working principle of Vertical Shaft Impact (VSI) crushers

The materials fall into impeller with high-speed rotation vertically. On the force of high-speed centrifugal, the materials strike to the other part of material in a high speed. After mutual impacting, the materials will strike and rub between the impeller and the casing and then be discharged straight from the lower portion to form a closed multiple cycles. Final product is controlled by screening equipment to meet the requirement.

The VSI VSI Sand Maker has two types: rock-on-rock and rock-on-iron. Rock-on rock is to process abrasive material and rock-on –iron is to process normal material. The production of rock-on-iron is 10-20% higher than rock-on-rock.

Product Data

Technical Data of VSI Sand Maker:

| Model | Max Feed Size (mm) | Rotor Speed (r/min) | Throughput (t/h) | Motor Power (kw) | Overall Dimensions (L×W×H) (mm) | Weight (kg) |

| VSI3000 | 45(70) | 1700-2000 | 30-60 | 75-90 | 3080×1757×2126 | ≤5555 |

| VSI4000 | 55(70) | 1400-1620 | 50-90 | 110-150 | 4100×1930×2166 | ≤7020 |

| VSI5000 | 65(80) | 1330-1530 | 80-150 | 180-264 | 4300×2215×2427 | ≤11650 |

| VSI6000 | 70(80) | 1200-1400 | 120-250 | 264-320 | 5300×2728×2773 | ≤15100 |

| VSI7000 | 70(80) | 1000-1200 | 180-350 | 320-400 | 5300×2728×2863 | ≤17090 |

| VSI8000 | 80(150) | 1000-1100 | 250-380 | 400-440 | 6000×3000×3420 | ≤23450 |

| VSI9000 | 80(150) | 1000-1100 | 380-600 | 440-630 | 6000×3022×3425 | ≤23980 |